Description

Product Features

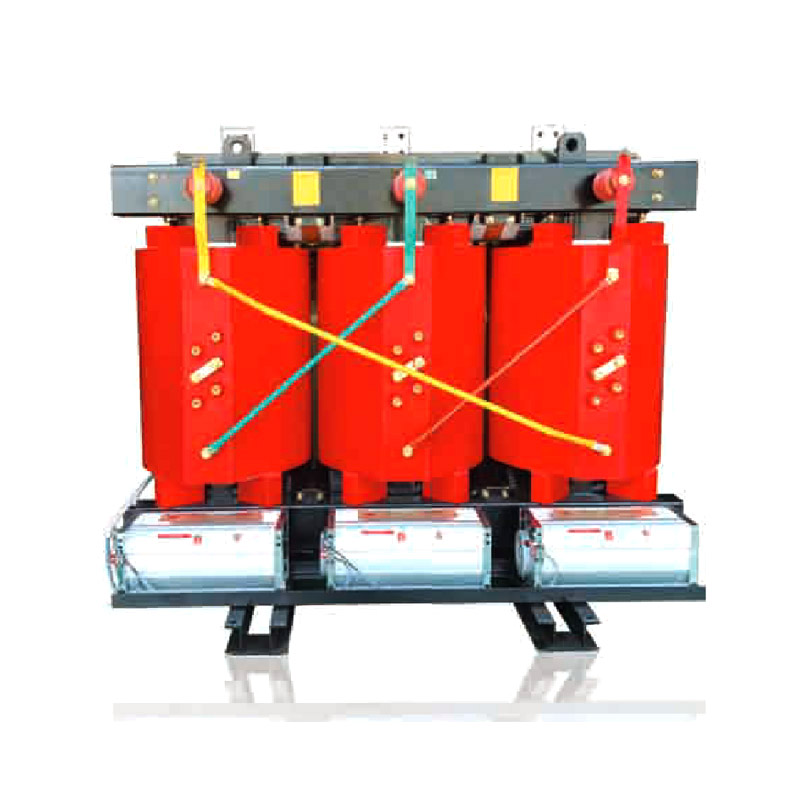

Security, flame retardant fire prevention, no pollution, can directly mounted in load center.

Maintenance free, easy installation, integrated operation cost is low.

Moistureproof performance is good, can be in 100% humidity, after the normal operation of the action can be put into operation gets.

Dry Low df, local put power, low noise is small, cooling ability, forced air cooling conditions can be rated load operation 150%.

Equipped with perfect temperature protection control system for transformsr, provide a reliable guarantee safe operation.

High reliability, according to the product to have already been put into operation, the operation reliability of products has reached the lnkrnational advanced level.

Structure characteristics

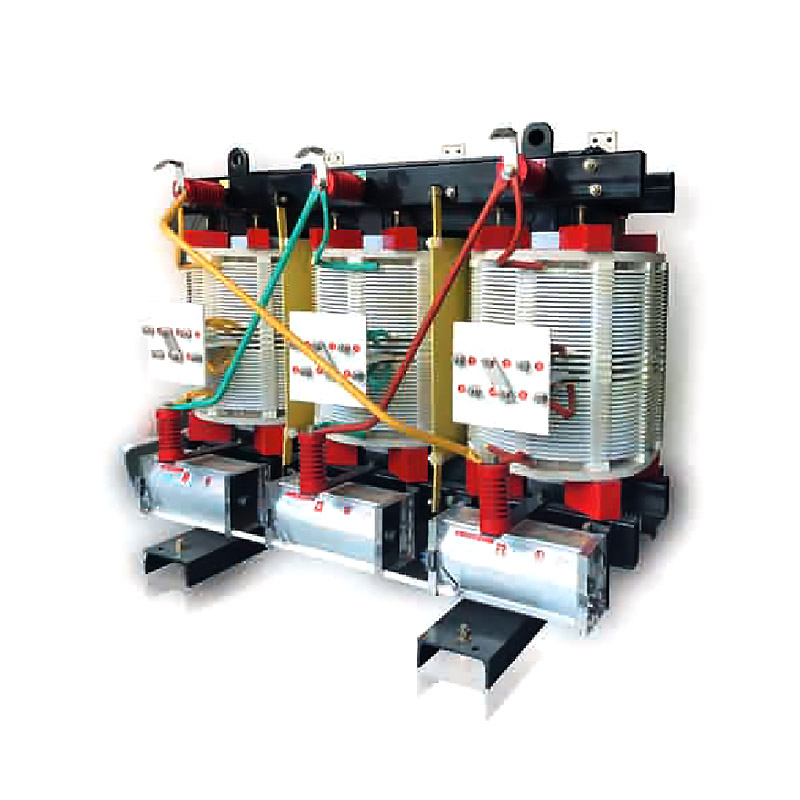

Box coil: low voltage winding adopts segmental copper foil, along with F grade in the low-pressure foil insulation turms on special around around the system. FoiI type coils has solved the low voltage, large currenl coil shorl-circuit stress around the product, Ann circle imbalance, cooling effect is poor, exist around the system spiral Angle, artifi-cially welding quality unstable outstanding problems. At the same time I company winding ends potting with resin,curing forming, moistureproof antifouling. Fuses copper platoon diameter argon arc welding automatic welding.

Temperature control device: transformer USES BWDK series temperature sensor signal thermometer, buried in the low-pressure coil, upper automatic detection and touring show phase of their respective working temperature coil and overtemperature alarm and tripped function.

FAQs

Our recommendation is that you buy a purpose-built step-up transformer instead of reverse feeding when possible.

Learn more about reverse-feeding transformers in this article.

The DGA has long been the most reliable and accurate method for determining the internal health of oil-filled transformers. The analysis requires drawing an oil sample from the unit, extracting the gasses from the sample, and analyzing the gasses through gas chromatography. The results of the chromatography tell the lab about different problems that may be arising inside the transformer. Some modern transformers have gauges on them that read levels of dissolved gasses in the oil in real time. But usually, the oil must be drawn and sent to a lab.

If you are unsure if an autotransformer is compatible with a particular piece of equipment, we recommend contacting the equipment manufacturer. However, as a general rule, this issue goes beyond the scope of an equipment manufacturers’ specifications since it is largely dependent on the existing electrical system configuration, where the equipment is installed, and local code requirements.

One hard and fast rule around autotransformer use: If the machine requires a neutral, and your system does not have one, an isolation transformer is required to create that neutral. Autotransformers do not create their own neutrals.

If your primary concern is lead time, repair is almost always quicker than buying a new unit—and this is especially true given the current supply chain crisis.

However, replacing the damaged unit with a reconditioned one can sometimes be just as fast or faster than repairing or replacing with a brand new unit. If an available reconditioned unit matches the dimensions of the unit in need of repair, you can sell the failing one and replace it with the reconditioned one.

Maddox has thousands of reconditioned, ready-to-ship transformers in stock for most common voltage configurations. These are typically available with a warranty comparable or identical to the warranties of newly manufactured units.